Burial Studies

STUDIES OF BRONZE GROUPS FROM INDIVIDUAL GRAVES

Comparison of compositional and microstructural data between successive archaeologically defined phases, each of which are several centuries long, allows for only a broad-brush interpretation of possible changes in the copper-based technology at Tepe Hissar (see Initial Analysis). To gain some sense of intrinsic variability of metalworking within a much shorter time-frame requires the study of items that most likely were made within just year or so of one another, the most obvious circumstance for this being where the bronzes occur within the same burial. Only two burials provided enough copper-based artifacts for such a study, six in the case of grave DF79 X13, and four in the case of grave DG53 X8. Technical studies for all other burials were limited to the availability of two bronzes (9 instances: discussed below), or just one (all others).

Grave DF79 X13 (from Phase III)

The bronzes studied include 5 single-coil bracelets all of roughly equal size, and one pendant. As is true of all the Hissar copper-based artifacts analyzed in the MASCA program, none of these 6 artifacts contain any significant amount of tin (i.e., <0.020%, by weight).

33-22-557: bracelet

As, 2.6%; Pb, 1.8%; Ni, 0.041%

33-22-558: bracelet

As, 2.7%; Pb, 1.6%; Ni, 0.036%

33-22-559: bracelet

As, 2.4%; Pb, 1.2%; Ni, 0.062%

33-22-560: bracelet

As, 2.5%; Pb, 1.3%; Ni, 0.076%

33-22-572: bracelet

As, 2.6%; Pb, 1.3%; Ni, 0.044%

Mean values: As, 2.6% ± 0.05%; Pb, 1.4% ± 0.11%; Ni, 0.052% ± 0.007%

These data display such a limited degree of scatter (cf., the graphs for "Grave pairs" below) that all these bracelets most likely were produced from the same metal stock. The same cannot be said of

33-22-543: pendant

As, 6.1%; Pb, 0.25%; Ni, <0.014%

the As-content of which is actually the highest measured in the Hissar analytical program (see Initial Analysis).

Above: 33-22-559 & -560

T wo bracelets corroded together

Grave DF79 X13

Grave DG53 X8 (from Phase II)

The bronzes studied include 3 anklets of roughly equal size and a complete weaving spindle set.

As is true of all the Hissar copper-based artifacts analyzed in the MASCA program, none of these 5 artifacts contain any significant amount of tin (i.e., <0.020%, by weight).

33-22-553: anklet, single-coil

As, 5.45%; Pb, 0.47%; Ni, <0.014%

33-22-554: anklet, single-coil

As, 3.89%; Pb, 0.16%; Ni, <0.014%

33-22-555: anklet, double-coil

As, 3.69%; Pb, 0.29%; Ni, <0.022%

Mean values: As, 4.3% ± 0.6%; Pb, 0.31% ± 0.09%; Ni (all), <0.022%

The similarity of the data for the anklets (cf., the graphs for "Grave Pairs" below), suggests that they may have been produced from the same ingot as metal stock.

33-22-116, a-c: weaving spindle

a. rod; b. ring; c. whorl

As, 0.97%; Pb, 0.52%; Ni, <0.015%

As, 0.25%; Pb, 0.74%; Ni, <0.014%

As, 0.34%; Pb, 0.55%; Ni, <0.067%

The similarity of the data for the three parts of the weaving spindle suggest that they most likely were produced at the same time from just one ingot as metal stock.

Above: 3-22-116, a-c

Weaving spindle

Grave DG53 X8

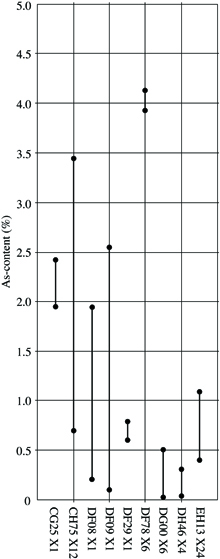

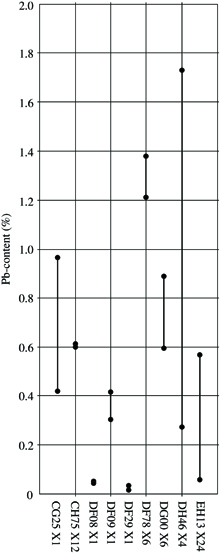

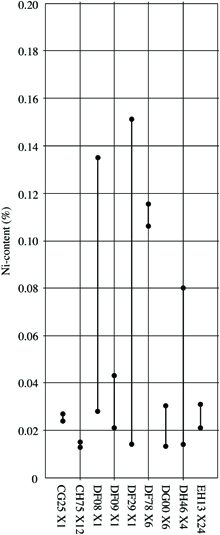

GRAVE PAIRS

While there is a general compositional consistency among artifacts in the two burials discussed above, it appears that the same cannot be said of most burials at Hissar. In the nine instances of burials where there were two bronzes available for analysis, the variability in the data was quite appreciable. This variability probably reflects compositional differences in the local metalworkers ingot stock. If that is true, then it seems unlikely that those metalworkers were aware of the practical advantages that the presence of arsenic and lead could provide them.

Grave EH13 X24 dates to Phase I

Graves CG25 X1, DF78 X6, and DH46 X4 date to Phase II

Graves CH75 X12, DF08 X1, DF29 X1, and DG00 X6 date to Phase III