Glossary

|

Glossary of Metallurgical Terms |

|||||

|

|

|||||

|

Annealing is a heat treatment applied to metals, its principal effects being the softening of previous cold working through re-crystallization, relief of internal stress, and the homogenization of composition. Annealing can be used to control grain size; the higher the temperature, the larger the grain will grow. |

|||||

|

|

|||||

|

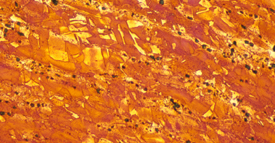

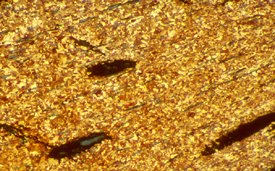

Banding is a microstructural feature that reflects the persistence of chemical segregation that was present in the original casting process. It may be completely or partially removed by the effects of hot-working and/or lengthy annealing. The bands themselves are often well delineated by the preferential alignment of inclusions. |

|

Micrograph (magnification, 200x) for a bronze chisel from Tepe Gawra (northern Mesopotamia) |

|||

|

|

|||||

|

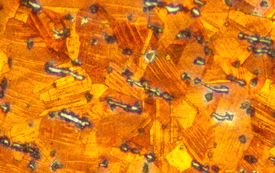

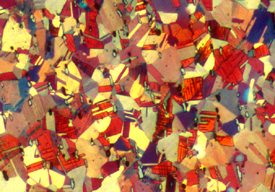

Cold working is a shaping operation (e.g., hammering, bending, or rolling) that is carried out at a temperature and rapidity that results in an increase in both strength and hardness. The effects of cold working appear in a bronzes microstructure as flattened grains that have striations (strain lines) within them. In contrast, hot working is a shaping operation that is carried out at a temperature and rapidity that does not result in an increase in strength or hardness. However, if well controlled, it can also be used to manipulate grain size. While hot working results only in elongation of inclusions, cold working also causes them to fracture. |

|

Micrograph (magnification, 400x) for a bowl from War Kabud (Luristan) |

|||

|

|

|||||

|

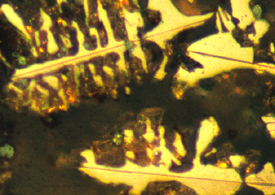

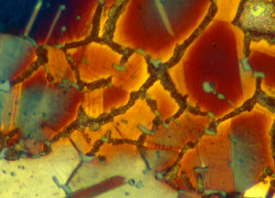

Dendrites are crystals that usually are formed during casting, by precipitation out of the molten metal, as it cools in the mold. They are characterized by a tree-like pattern composed of many branches. |

|

Micrograph (magnification, 200x) for a door fixture from Nippur (southern Mesopotamia) |

|||

|

|

|||||

|

Eutectoid transformation during the casting of a metal is the separation of a single phase solid solution into two others at a specific temperature. In bronze, this transformation occurs at 520 degrees Celsius, to form a layered structure that consists of the a and d phases. In a bronze microstructure, this eutectoid may appear as a distinctive inter-granular constituent. |

|

Micrograph (magnification, 400x) for a fragmented staff-top from Bard-I Bal (Luristan) |

|||

|

|

|||||

|

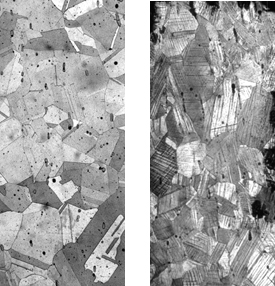

Grain size for nonferrous metals, such as copper, is expressed as the average grain diameter in millimeters at a magnification of 75x. Standard charts may be used to make a visual estimation of this: GS1 to GS10 covers the range from very coarse to very fine. In cast metal, grain size is controlled by the temperature of annealing. Thereafter, it can be manipulated by varying the degree of coldworking and annealing. |

|

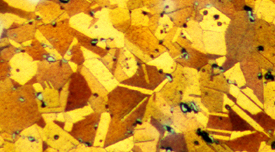

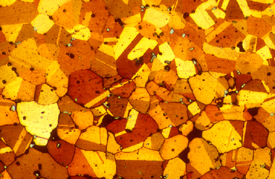

Micrograph (magnification, 200x) for the fine-grained structure (standard GS, 8-9) of a fragmented blade from Tepe Gawra (northern Mesopotamia) Micrograph (magnification, 200x) for the coarse-grained structure (standard GS, 9.5-12.5) of a snake from Tepe Gawra (northern Mesopotamia) |

|||

|

|

|||||

|

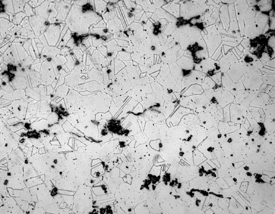

Intergranular corrosion is a preferential attack and penetration of the boundaries between grains, filling the region with corrosion products such as complex copper chlorides, carbonates, etc. |

|

Micrograph (magnification, 300x) for a bracelet from Bard-I Bal (Luristan) |

|||

|

|

|||||

|

Matte is a complex metallic sulfide produced during the smelting of copper- and lead- containing sulfide ores. It may contain significant amounts of iron, if it derives from an ore such as chalcopyrite (CuFeS). Remnants of matte are sometimes entrapped as globular inclusions during casting of the metal. |

|

Micrograph (magnification, 300x) for a snake from Tepe Gawra (northern Mesopotamia) |

|||

|

|

|||||

|

A metal owes its microhardness to some extent to its composition, but for the most part to the nature of its microstructure. In practice, microhardness is defined in terms of the method used to measure it, the preferred being a standardized penetration test. The three most commonly used are named after their originator; thus Brinnell, Vickers (as a VHN number), or Rockwell A, B, C, etc. In such a test, the resistance the metal offers to penetration is determined with a loaded indentation tool of fixed geometry. |

|

Left: Micrograph (magnification, 200x) for an arrowpoint |

|||

|

|

|||||

|

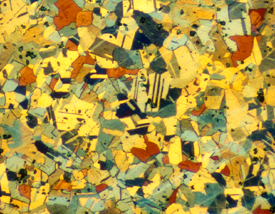

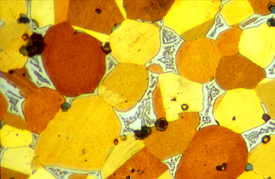

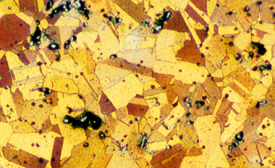

Polyhedral grains are crystals bounded by essentially straight sides that often meet at an acute angle. In contrast, the surfaces of equiaxed grains are crystals roughly equal in all dimensions, and so they tend to have a more rounded shape. |

|

Micrograph (magnification, 200x) for a fragmented boss from Tepe Gawra (northern Mesopotamia) Micrograph (magnification, 100x) for a dagger from Bard-I Bal (Luristan) |

|||

|

|

|||||

|

Re-crystallization is a time and temperature dependent heat treatment used to produce new grains in a previously cold-worked metal that are free of strain lines (see Annealing above). At the start of this process, grains will tend to be very fine. |

|

Micrograph (magnification, 100x) for the fine-grained structure of a dagger from Kutul-i Gulgul (Luristan) |

|||

|

|

|||||

|

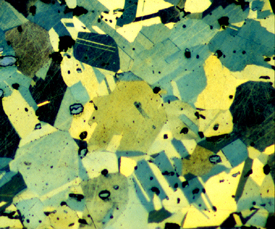

Twinning is a rearrangement of a metals atomic structure that results from the combined effects of cold working and re-crystallization. It is characterized by parallel-sided forms within a grain. |

|

Micrograph (magnification, 100x) for an arrow point from Bard-I Bal (Luristan) |

|||

|

|

|||||

|

Etching is a preferential chemical attack that brings out significant metallographic features that may have implications for an artifacts physical and mechanical properties. Etchants primarily pick out differences in composition and grain orientation. The ingredients for those most often used in MASCAs archaeometallurgy projects are listed below, with their usual volume and/or weight proportions. |

|||||

|

|

|||||

|

|||||