The Early History of Mold-blowing

Mold-blown jug enscribed ENNIWN EITOICE

("Ennion made it")

We have a reasonably good idea when the technology of mold-blowing was introduced. A beaker from Cosa in western Italy, that has a mold seam hidden amid its band of palm branches, and a fragment of the motto, “Let the buyer be remembered” on it, has been dated close to A.D. 45. Contexts of similar date at various places in northern Italy have yielded two-handled cups inscribed with the same motto and the phrase "Ennion made me." Ennion's name crops up regularly for a couple more decades, but others occur as well, such a Jason, Meges and Neikaios, and someone self-titled "Aristeas the Cypriote," who some think was a mimic of Ennion’s style.

The common feature among these mottoes and names is that they are all Greek. This fact would place the innovation of mold-blowing firmly in the provinces of Judaea and/or Syria. The finding of so many Greek-inscribed vessels on the Italian mainland is consistent with the idea that skilled craftsmen often were simply enslaved in the eastern Mediterranean and transported to Italy to strengthen the workforce there.

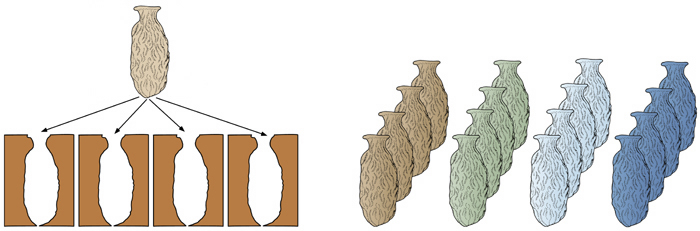

Mold-blowing of glass was not without its difficulties. As a glassworker blew a hot glass bulb into the mold cavity, it would be forced against the outline of the mold's pattern and would tend to pool and thicken in some of the mold’s recesses. Subsequently, when the glass vessel was cold and rigid, it would sometimes be locked into various parts of the mold's surface. Too much time and effort was invested in preparing any kind of mold for it to be cracked open and discarded after just one use. The glassworker's solution was to use a mold with two or more parts, each of which could be drawn away from the glass after each use, then bound together again for the next one.

Some of these multi-part molds were of stone or sheet bronze, in which case they were produced individually. Most of them, however, were of clay and created in quantity, as secondary castings from a pre-sculpted model of fired plaster.

The use of a sculpted plaster model (top left) allows the production of several identical molds (bottom left), each of which can be used to produce numerous vessels (in this instance, a small date-shaped flask) in a wide range of colors.